High Torque Brushless Motors for Factory Automation

Brushless motors are ideal for factory automation applications such as conveyors that carry materials to different locations for various processes. A new 300 W motor and dedicated single-phase and three-phase drivers have been added to both the advanced  as well as the simple-to-use

as well as the simple-to-use  . The new motor is offered in a round-shaft configuration or with a variety of gear options for high torque applications.

. The new motor is offered in a round-shaft configuration or with a variety of gear options for high torque applications.

400 W parallel shaft helical gear motors, foot mount parallel shaft helical gear motors, and right-angle hollow shaft hypoid gear motors have been introduced for the BLE2 Series.

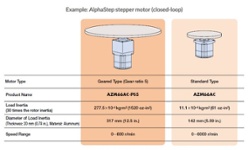

Gear Motor Comparison

|

When to Use BLE2 Series or BMU Series?

|

- When AC power supply is desired

- Conveyors that require tight speed regulation

- Applications that require high torque but have limited space

- BLE2 Series is an ideal replacement for BLF Series

- BMU Series is an ideal replacement for BLU Series

|

For applications such as AGVs or AMRs, brushless motors with DC drivers, such as the compact  and the high power

and the high power  , are recommended.

, are recommended.

Motor Selection for Factory Automation

Factory automation involves a mix of different motion control applications to achieve efficient production for manufacturers. Stop accuracy, speed-torque characteristics, duty cycle, IP rating, and network capabilities are some factors that determine the best motor for the application.

| Washdown Conveyor |

XYZ Pick & Place |

|

|

Browse our applications page for product ideas. Our helpful  are available to assist you with anything you need during the product selection process.

are available to assist you with anything you need during the product selection process.

Engineering Notes to Help with Factory Automation

Interested in improving product knowledge? Subscribe to our Engineering Notes for application tips and basic product training. Here are 4 recent posts to help resolve common factory automation challenges, such as space and maintenance optimization.

Flexible Configurations

For Hollow Rotary Actuators |

10 Advantages of Geared Motors |

|

|

Monitor Your Machine

Like a Traffic Light System |

Minimizing the Effect of

Load Fluctuations for Mixers |

|

|

Recommended Literature for Factory Automation

The 2020~2021 Product Guide is the first eBook we've ever produced and introduces many products that can be used for factory automation. The white paper highlights the differences between motors typically used for conveyors.

| 2020~2021 Product Guide (eBook) |

Brushless DC Motor vs AC Motor

vs Brushed Motor (White Paper) |

|

|